140,70€ w/o VAT per box 5 units

Fast-curing epoxy adhesive in a twin-syringe for reinforced bonding in cases of significant surface roughness or high moisture

Mechanical fixing kit for surfaces unsuitable for self-adhesive installation (includes 1 drill bit + 1 PZ1/PZ2 screwdriver + 40 wall plugs and screws)

Bag of 50 anchors and screws for mechanical fixing on surfaces unsuitable for self-adhesive mounting

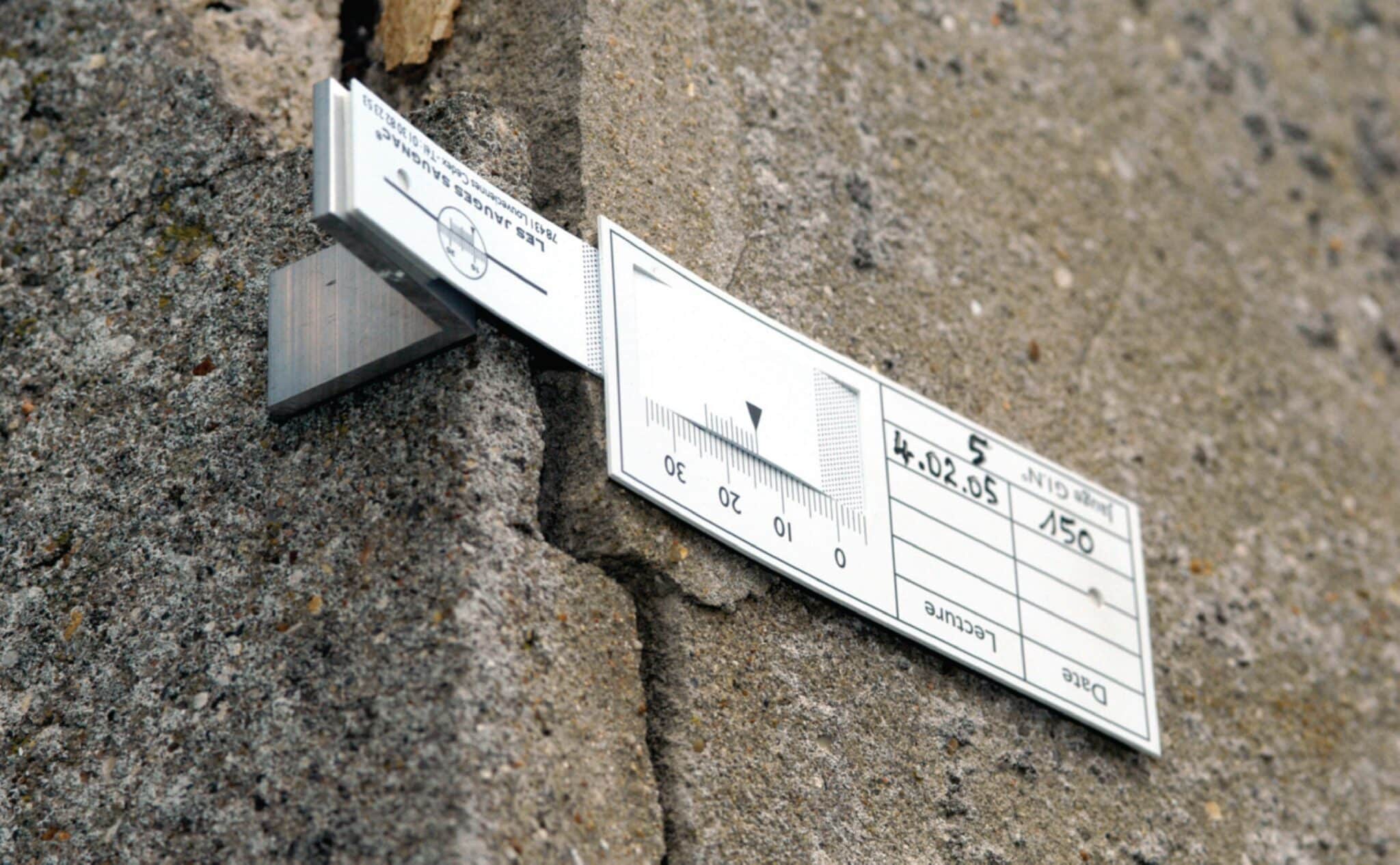

For measuring the variation in a crack in a vertical or horizontal internal angle (with self-adhesive tabs and 1 impact anchor).

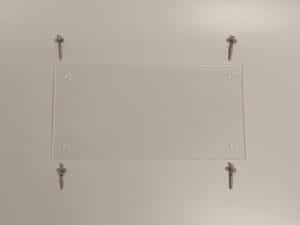

Protection with anti-UV filter for G6 gauges fixed outside. Delivered with impact anchors.

Pour obtenir un devis ou nous poser des questions sur le produit, n’hésitez pas à nous contacter :

If you would like a quotation or have any questions about the product, please contact us: