Saugnac G1 crack monitor, an effective alternative to plaster crack monitors

In monitoring wall and structural cracks, traditional plaster crack monitors come with significant limitations. To address these challenges, the G1 gauges provide a simple and efficient alternative, offering several advantages over plaster crack monitors.

How Plaster Crack Monitors Work

The principle is straightforward: a plaster monitor is sealed or placed over the crack. If, after some time, the plaster monitor cracks, the crack is considered “active.” This method allows for a visual detection of crack progression.

Limitations of plaster monitors for crack monitoring

While this method may seem clever, it has major drawbacks that limit its usefulness:

Unreliable Fixation

Depending on the surface where the crack is located, the plaster monitor may not adhere over time. In such cases, the plaster detaches, rendering it completely ineffective.

No Quantitative Measurement

A plaster monitor only indicates that a crack has widened. It provides no numerical data, making it impossible to perform a thorough diagnosis or quantify the crack’s progression.

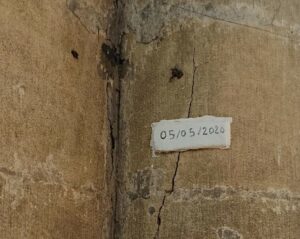

No Dated History

At best, the plaster monitor may include the date it was applied. Often, this information is missing, making it impossible to draw meaningful conclusions.

Inability to Track Cycles

Plaster monitors cannot track the opening and closing cycles of cracks, especially those caused by seasonal ground movement. They fail to quantify changes, determine stabilization, or verify the effectiveness of repairs.

A reliable alternative : the G1 gauge

Without resorting to complex and costly solutions, it is possible to monitor crack evolution using simple and effective tools. To meet this need, we developed the G1 gauge family, offering numerous advantages over plaster crack monitors.

Precision for In-Depth Analysis

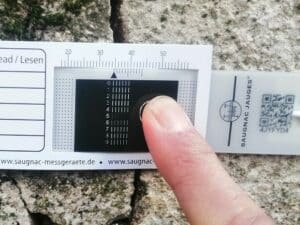

The G1 crack monitors offer a resolution of 0.1 mm (and even 0.05 mm for the G1+). Readings are straightforward, using a vernier principle or directly via a smartphone with the Saugnac app for the G1 gauge. The G1+ crack monitors features a patented simplified reading system.

Data Enrichment and History

G1 crack monitors include a marking zone for recording measurements with the provided pen.

Each gauge also has a unique identifier and QR code, enabling data storage in the cloud via the free Saugnac monitoring app. The app allows users to add photos and capture temperature and humidity data, improving the reliability of crack diagnostics.

Tracking Crack Cycles

The crack monitors feature a sliding arm mechanism that tracks both the opening and closing of cracks. This capability enables monitoring seasonal variations, temperature effects, and humidity changes—an advantage over plaster monitors.

Durable Fixation

G1 gauges come with technical adhesives ensuring long-term adhesion when properly installed. Additional fixation methods are available depending on the context.

The G1 gauge family is a superior alternative to plaster crack monitors, offering precise, reliable, and long-lasting solutions for crack diagnostics. These tools provide the data needed for accurate, long-term assessments and repair validation.