126,50€ w/o VAT per box 10 units

Technical specifications

|

||||

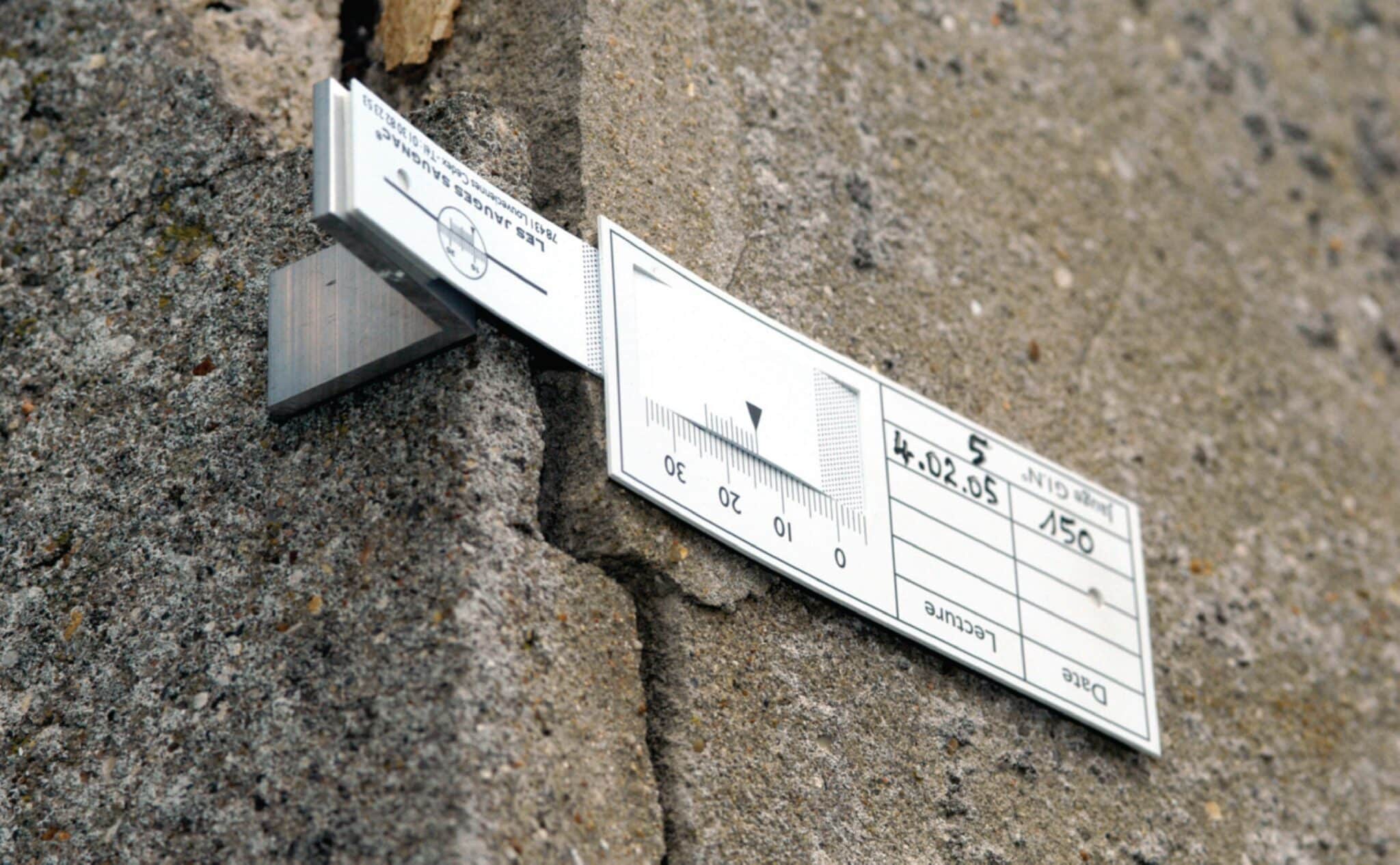

How to fix the G1 crack monitor?In order to most effectively measure the evolution of the crack, the gauge is usually fixed at the widest point of the crack or in the middle of the crack. The G1 gauge is made of a material that is flexible enough to accommodate and follow the movement of irregular, convex or concave surfaces. There are two possible methods of fixing:

A: tap-screws / knock-in dowels

|

||||

Installation tips

Ideally, position the vernier triangle between 10 and 11 with the two speckled bands appearing on the right and left. The objective is to centre the pull tab. Do not try to position the vernier triangle

Position the pin of the folding bar in the middle of the slotted hold to absorb any movement. |

||||

How to measure crack in angle?The G1 family of gauges is supplied with a folding bar that allows for corner mounting.

|

||||

How to protect the G1 crack monitor?

In high-traffic areas where there is a high risk of damage, the removable E1 crackmeter can be used with transparent plates. After measurement, only the plates remain on the support, preventing any possible damage. |

||||

How to read the G1 crack monitor?The upper section is graduated in mm from 0 to 30: this is the measurement scale. The lower section moves: this is the 1/10th mm vernier (10 divisions of the vernier correspond to 9 mm on the measurement scale).

Reading a measurement with a decimal

a) Reading the millimeters:

The pointer

b) Reading the decimal:

Find the line on the vernier which is exactly aligned to a line on the measurement scale. In this example, graduation 8 on the vernier is in line with graduation 21 on the measurement scale. The decimal reading is thus 8/10th of a mm. The overall reading is therefore 13,8 mm.

Even simpler to read and more accurate: G1+ gauge with “direct” readout (resolution: 0,05mm) or E1 removable digital crack meter (resolution: 0,01mm).

|

||||

Download the Saugnac.app application to monitor your measurementsThe Saugnac web application, which is completely free of charge and has no limitations, is available on PC or smartphone from https://saugnac.app. It allows you to :

Find all the explanations on how the application works |

||||

Download monitoring Excel file

This Excel file is very easy to use: you just have to duplicate a sheet for each site or construction site observed with the possibility to follow up to 10 gauges. Note that the impact of the expansion coefficient on the G1 gauge measurement is very small (about 9 micrometers every 1°C). Here is an example of the type of monitoring obtained with the file:

|

Protection with anti-UV filter for G1 gauges fixed outside (delivered with impact anchors)

Fast-curing epoxy adhesive in a twin-syringe for reinforced bonding in cases of significant surface roughness or high moisture

Mechanical fixing kit for surfaces unsuitable for self-adhesive installation (includes 1 drill bit + 1 PZ1/PZ2 screwdriver + 40 wall plugs and screws)

Bag of 50 anchors and screws for mechanical fixing on surfaces unsuitable for self-adhesive mounting

For measuring the variation in a crack in a vertical or horizontal internal angle (with self-adhesive tabs and 1 impact anchor).

Pour obtenir un devis ou nous poser des questions sur le produit, n’hésitez pas à nous contacter :

If you would like a quotation or have any questions about the product, please contact us: