Vous souhaitez un renseignement pour

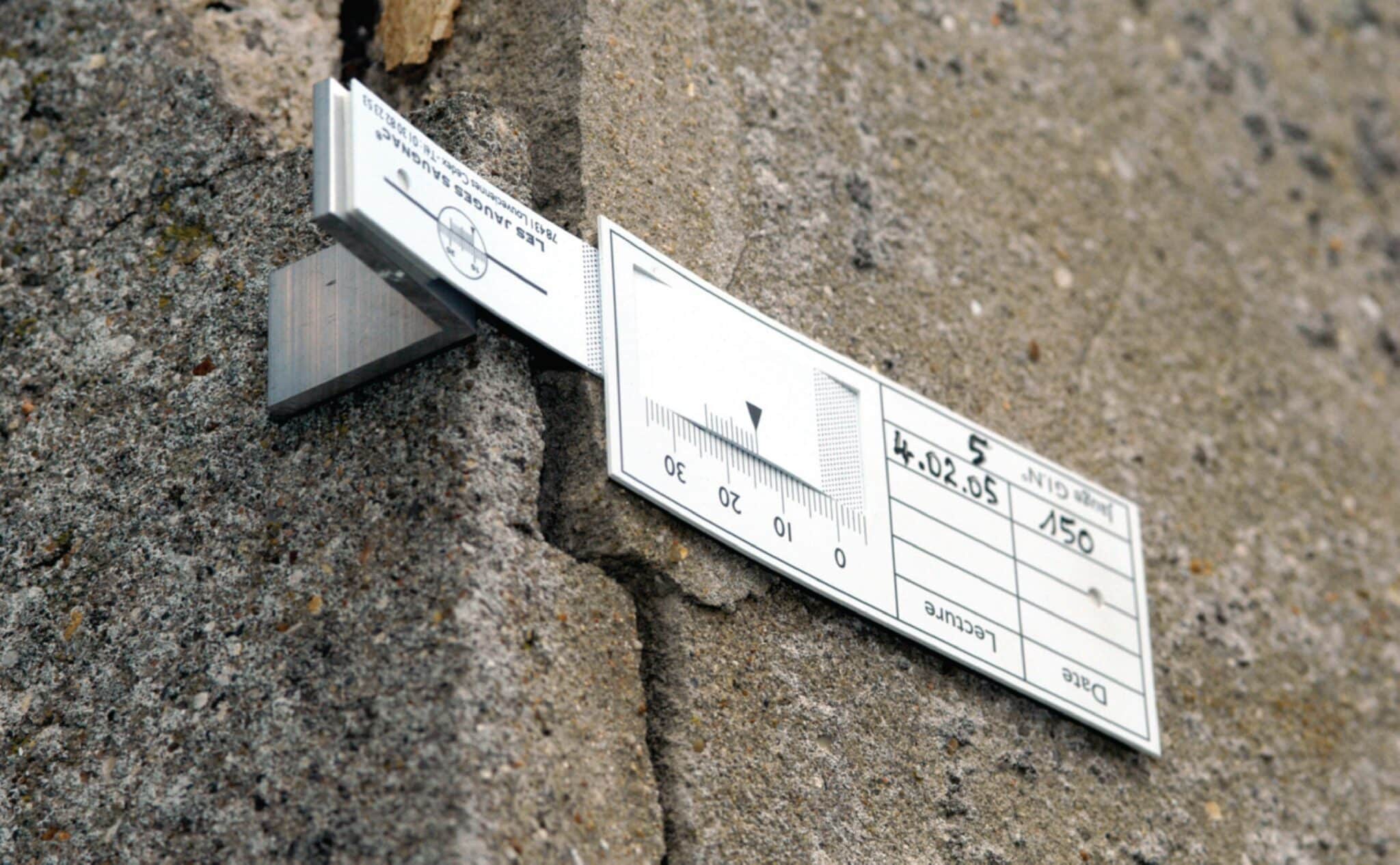

G1+ Gauge

Pour obtenir un devis ou nous poser des questions sur le produit, n’hésitez pas à nous contacter :

- par email sur info@saugnac-jauges.fr

- par téléphone au 09 62 07 18 68 (prix d’un appel local)

152,00€ w/o VAT per box 10 units

Technical specifications

|

||

How to fix the G1+ crack monitorFor the most accurate monitoring, attach the crack monitor at the widest point of the crack, typically in the middle. The G1+ gauge is made of flexible material that adapts to irregular, convex, or concave surfaces. Two fixing methods are possible:

|

||

Installation tipsPosition the crack monitor where the crack is widest. It can be placed across vertical, horizontal, or oblique cracks. The flexible G1+ gauge follows the surface movement accurately.

|

||

Measuring cracks in cornersThe latest G1+ gauges (from mid-2025) have a groove marked on the folding tab to facilitate corner mounting without extra accessories. Earlier versions include a foldable tab with a thin section to guide bending.

Example corner installations:

|

||

Protecting your G1+ gauge

For high-traffic zones, use the removable E1 crackmeter with transparent plates. Only the plates remain on the structure after measurement, preventing damage. |

||

Reading the G1+ digital crack monitorThe G1+ gauge provides a digital readout in tenths of mm. Each 1/10 mm movement of the tab blocks a row of 6 white lights corresponding to digits 0–9. Subtract the first reading from the second to determine crack growth.

Crack growth over 90 days = 0.55 mm. Use the vernier if verification is needed (instructions in G1 product sheet). |

||

Download Saugnac.appFree PC and smartphone application at https://saugnac.app. Features:

Full instructions: how the app works |

||

Download Excel monitoring file

Use the Excel file to track up to 10 gauges per site. The file adjusts measurements for temperature-related expansion. If no temperature reading is available, leave blank. Note: Expansion effect on G1+ readings is very small (~9 µm per 1°C). |

Protection with anti-UV filter for G1 gauges fixed outside (delivered with impact anchors)

Fast-curing epoxy adhesive in a twin-syringe for reinforced bonding in cases of significant surface roughness or high moisture

Mechanical fixing kit for surfaces unsuitable for self-adhesive installation (includes 1 drill bit + 1 PZ1/PZ2 screwdriver + 40 wall plugs and screws)

Bag of 50 anchors and screws for mechanical fixing on surfaces unsuitable for self-adhesive mounting

For measuring the variation in a crack in a vertical or horizontal internal angle (with self-adhesive tabs and 1 impact anchor).

Pour obtenir un devis ou nous poser des questions sur le produit, n’hésitez pas à nous contacter :

If you would like a quotation or have any questions about the product, please contact us: